The benefits of integrating a permit to work system with other applications

An electronic permit to work system will work across several operational areas to improve performance, maintenance and safety at a plant. Each of these areas is supported by a software application and in many cases, these applications are not integrated.

The case for integrating the electronic permit to work system with these applications is compelling and there will be real benefits to doing so. However, a successful integration will require careful analysis of the business need, a clear requirement definition, good system design and effective project management.

In this article, we take a look at some of the benefits of integrating IntelliPERMIT with other applications, and then we offer a few pointers as to the key success factors for such a project.

Example integrations

Site access control: Integrating the permit system to the site access control system allows additional safety controls to be implemented. For example, a person can be prevented from leaving a site if there is an active permit requiring his or her sign-off. Or a person might be prevented from entering a restricted area unless he or she holds a valid permit. Over time, data from the site access control system can be analysed together with data from the permit system. This could generate new insights into the productivity of teams and by identifying patterns can help solve recurring problems.

Training and competency records: Each participant in the permit to work and isolation process needs to be trained, competent and authorised for the role that they are expected to perform. The competency information for both employees and contractors held in external systems can be used to automatically check that all necessary training has been done, and all the necessary certifications are still current.

Project management system: During shutdowns or small capital projects, detailed work is planned in advance using a project scheduling application. By integrating the permit with the scheduling software, it becomes easier to prepare permits in advance, thereby reducing wait time and improving productivity. Actual data from the permit system can then be used to update the schedule information in “near real-time”.

Work order management: Maintenance and safety are of course closely related, and it, therefore, makes sense to integrate relevant information from the EAM (Enterprise Asset Management) system to the electronic permit system. There are many benefits to this approach:

· a common equipment database is used for both safety and maintenance information;

· the safety aspects of hazardous maintenance tasks can be better controlled;

· job planning is improved; and

· better coordination between operations and maintenance teams can be achieved.

SCADA/PLC/DCS: Data in the process control systems can be used to cross-check information relating to process conditions, isolations and plant status. Carefully integrating the process control system with the permit to work system can improve the visibility of work in progress to process operators, provide early warning of abnormal hazardous plant conditions, better coordinate production and maintenance and more. Note: it is critical that data from these systems is not presented to users as any kind of confirmation that equipment has been correctly isolated and locked out!

IIoT Devices: The IIoT (Industrial Internet of Things) provides many opportunities to collect and correlate sensor information in the field. For example, field sensors can record the whereabouts and movements of people on site and relate this back to their permits. This improves control and visibility of work being done and ultimately improves safety. Other sensors can track the special tools and equipment needed for safe work. Real-time analysis of this data can in some circumstances even predict increased safety risk allowing for proactive steps to be taken to avoid an incident.

Contractor onboarding and induction systems: When occasional or part-time contractors enter a new industrial site, they can be unfamiliar with the site and this can pose an increased safety risk. Site induction and medical examinations are used to reduce this risk. When issuing a permit this onboarding and induction information can be used by the system to automatically validate that contractors have completed a valid induction, can do the required work, are fit and healthy to work and also hold the necessary qualifications.

Success factors when integrating these systems

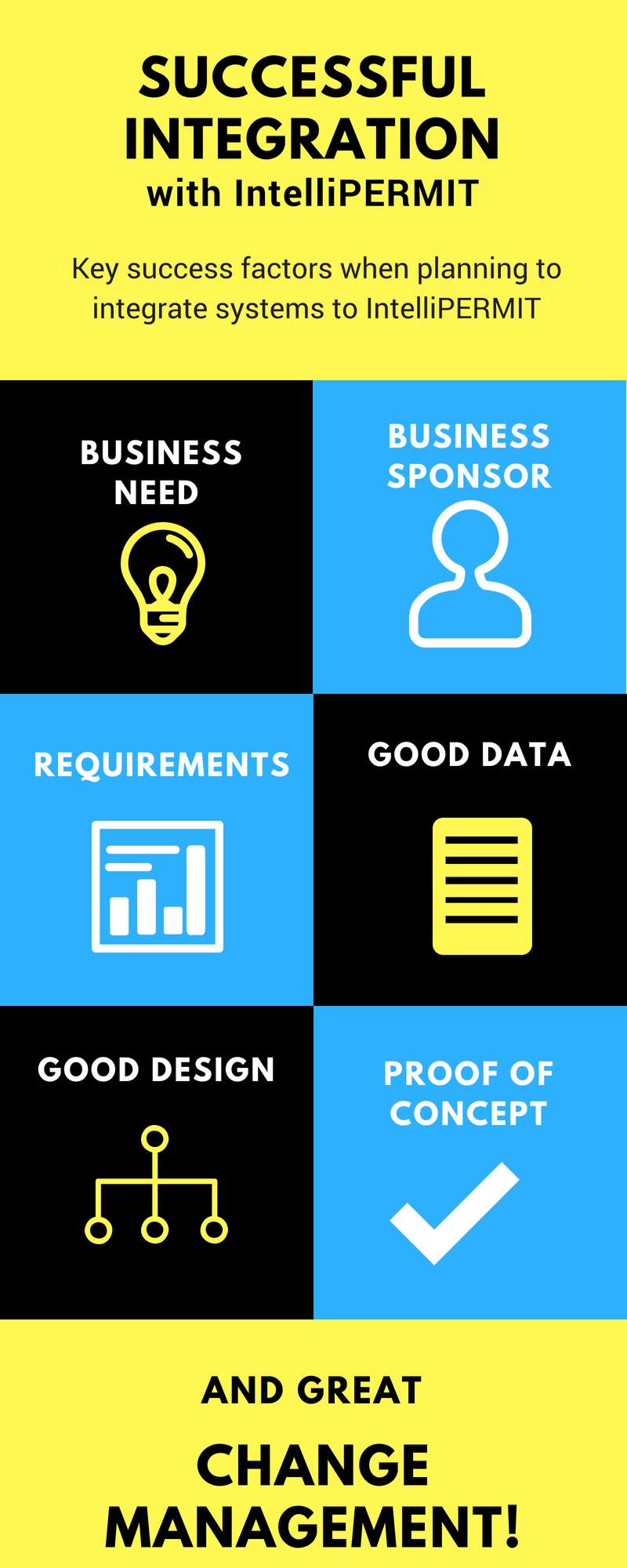

There are many more examples where significant benefits can be achieved by integrating these applications. From our experience, the success of this integration is strongly dependent on the approach followed. Here are seven key success factors which the IntelliPERMIT team consider very important when embarking on such a project:

- Business need: The underlying (real) business need for any integration must be determined up front and the anticipated benefits understood. As seen from the examples above, the benefits from such integrations could include improved safety, improved governance, reduced wait times, improved efficiency of work done etc. However, there should also be a shared understanding that these benefits are worth pursuing – a project of this nature will affect many people across multiple operational areas (even from different companies) and the project, therefore, needs to be strongly supported.

- Business sponsor: As for any project, a project sponsor should be identified. This person needs to have the necessary authority to make decisions. He or she should be a senior person and hold influence in the business – and will ultimately be held accountable for the success of the project.

- Requirements specification: Following the determination of the business need, detailed requirements should be developed. Producing a good requirements specification will involve a detailed analysis of how users will interact with the system (use cases, business process modelling and optimisation), the information flows and the various outputs from the system (reports, messages, displays etc.).

- Data quality: In order for integration to be effective, it is critical that the quality and latency of the source data is considered. Our experience has shown that if the data is required for effective operations, integration with IntelliPERMIT is a strong incentive to correct any deficiencies in the source data and ensure that it is kept up to date.

- Design: The system design should describe how the new software will work to achieve the requirements. This document should include a description of the integration architecture, how master data will be managed, database design, all software services, how the system will be configured, any user interface and deployment or upgrade aspects. As far as possible the integration should have a “fail-safe” – in other words, failure of one application or the integration software itself should be limited in impact and not seriously impact another critical system. The interfaces should also be “loosely coupled” – allowing for systems to be upgraded or substituted without replacing the integration.

- Proof of concept: To minimise project risk, a small, focused proof of concept (POC) can be planned, perhaps with a reduced functional specification. A POC can be run in a small section of the plant, thereby affecting fewer people until such time as the system has been optimised and proven. Following a successful POC, the new system can then be rolled out to the remaining plant areas as a project.

- Change management: Proper stakeholder involvement throughout the project is important, together with change management in the business. Recommended techniques for stakeholder management through the project are covered by methodologies such as the PMI’s PMBOK and the PRINCE2, and the IIBA’s BABOK.

- Upgrades or support and system maintenance: Over time the systems on site will need to be updated. Integration introduces additional dependencies making upgrade projects more difficult. These dependencies can be minimised through good architectural design upfront. The maintenance and support contract with your system vendor should ideally include the integration software. Ideally, you want a single point of responsibility to avoid the situation where vendors blame each other for something that no longer works after a system upgrade.

Conclusion

There are several benefits to integrating an electronic permit to work system with other operational systems or applications. We have covered a number of examples in this article, but we want to stress that it is important at the outset of any project to first determine the real business need. It is also important to follow a good project methodology for developing the interfaces. We have listed seven important success factors that from experience will greatly improve the prospects of success in your business.

If you have any questions or suggestions to improve this article, please contact the IntelliPERMIT team at Adapt IT.

Related Tag: Permit To Work System

Continue Reading

Q&A with IntelliPERMIT Consultant Lungelo Majozi

Explore the advantages of electronic permit to work (e-PTW) systems over paper methods, from faster investigations to specific hazard management. Learn how e-PTW enhances safety, prevents redundant isolations, and ensures accountability. Discover future trends like 3D modeling. IntelliPERMIT automates tasks, improves communication, and reduces costs, making workplaces safer and more efficient.

Powering Safety Innovations: An Exclusive Q&A with IntelliPERMIT Consultant Shirley Breytenbach

IntelliPERMIT transforms permit management with streamlined processes, competency-based approvals, and real-time visibility. Ensure regulatory compliance, enhance worker safety, and boost operational efficiency. The system offers seamless integration, empowering organisations to proactively mitigate safety risks.

Safety Software Implementation Success : An Exclusive Q&A with IntelliPERMIT Consultant Henry Boshoff

Unlock safety software success with IntelliPERMIT: Prioritise key features, secure user buy-in through change management, and foster collaboration. Set measurable goals, leverage incident data for proactive decisions, and ensure intuitive search capabilities. Streamline report generation and simplify scheduling and management of training, drills, toolbox talks, and audits. Overcome adoption challenges by addressing pain points and customizing the software. Enhance user adoption with automation and user-friendly interfaces. Evaluate safety software providers based on knowledge, experience, and adherence to standards—IntelliPERMIT excels. Easily integrate with existing systems through standard APIs. Opt for web-based software for accessibility and usability. IntelliPERMIT enhances safety practices and compliance.