Blog

Understanding the Work Health and Safety Act in Australia

Understand the WHS Act of 2011 and how flexible safety systems support compliance across Australia’s varied state regulations.

Hazard Identification & Risk Assessment: The Foundation of Safety Management

Learn how to identify hazards and assess risks to build a safer workplace with practical steps, examples, and best practices.

What is a Safety Management System? How It Prevents Incidents in High-Risk Industries

What is a safety management system? Learn how it prevents incidents, improves compliance, and protects workers in high-risk industries.

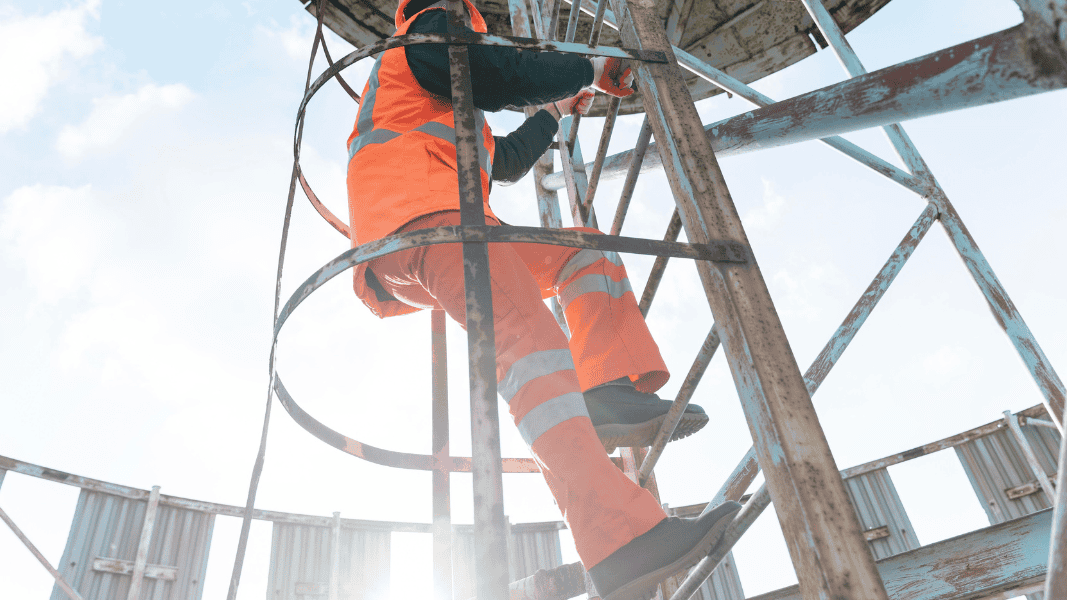

Working at Heights: How to Prevent Falls with Better Work Authorisation

Prevent falls from height with smarter work authorisation. Learn best practices and how IntelliPERMIT enhances safety at heights.

ISO Standards & Safety: How Certification Enhances Risk Management

Explore how ISO standards strengthen safety, compliance, and risk management in high-risk industries.

FMEA Analysis: A Proactive Approach to Risk Management in Industrial Safety

Proactive risk reduction with FMEA: identify failures early, improve safety, and enforce controls using digital tools like IntelliPERMIT.

Plan-Do-Check-Act (PDCA) in Safety Management: A Continuous Improvement Framework

Use the Plan-Do-Check-Act cycle to improve safety processes, reduce risk, and embed continuous improvement in your operations.

Job Hazard Analysis: A Data-Driven Approach to Workplace Safety

Learn how to conduct an effective job hazard analysis (JHA) to identify risks, improve safety, and streamline high-risk work procedures.

Lockout Tagout (LOTO) & Permit to Work: A Unified Approach to Energy Isolation

Discover how integrating Lockout Tagout (LOTO) with Permit to Work (PTW) enhances workplace safety, ensures compliance, and reduces operational risks.