Accessing the safety documents that matter using IntelliPERMIT

All safety management systems rely on control of formal documents. A system of document control ensures that exactly the right information is available to employees in their job. But how easy is it to find the right documents when they are most needed, when planning or executing work in dangerous areas of the plant?

Improving workplace safety is the responsibility of every individual in an organisation. It is up to management to provide safety leadership and to set safety policy. Safety management systems in turn ensure that safety policies are implemented. An effective safety management system needs to be fully integrated into the organisations existing management processes. A working safety management system will reduce the risk of workplace incidents. It will also yield many benefits such as improved compliance with regulations, enhanced reputation and improved morale.

All safety management systems rely on control of formal documents. A system of document control ensures that exactly the right information is available to employees in their job. The wrong version (such as a draft safety procedure or an older version) can have disastrous consequences and result in injury or harm to people and/or damage to equipment and the environment. Any changes to procedures or technical specifications should therefore be controlled so that only the right documents are used.

Safety Management Systems and Control of Safety Documents

Standards such as ISO 45001 help organisations implement an occupational health and safety (OHS) management system. ISO 45001 requires that “documented information be controlled” (7.5.3).

In theory this sounds very good. But in practice it can often be difficult for people in the field to access the right document. The reasons for this are varied and might include:

- Formal documents are controlled in a separate system and not all employees have direct access to this system, or they may be unfamiliar with it.

- The organisation of controlled documents does not necessarily align with the way work is being done. This makes finding the right information for the right step in the process difficult.

- Temporary employees need to be inducted and a typical “day-pass” induction might not necessarily cover all the relevant technical documents or safety procedures.Workers are often not aware of all the resources available to them to do their job safely.

- Security permissions are not always in place; a common situation is temporary workers who do not have network accounts.

We have seen that in typical industrial sites even the most basic of safety procedures, for example the most up to date permit to work procedure, is not readily available to most of the people working in the plant. If needed, individuals must request it or look for it in a separate system.

Clearly a balance is required between tight control of procedure documentation and making information easily accessible to all that need it.

Linking IntelliPERMIT with Controlled Safety Documents

Fortunately, IntelliPERMIT helps solve this problem by allowing controlled documents to be linked directly from the permit system so that they can be directly accessed at exactly the right time by the right people in the process. Linked documents, if required can be printed together with the permit itself and therefore be accessible to workers in the field.

Having documents linked into the permit process has the added advantage of a single interface for end users to access what they need, without the requirement for complex searches in a separate controlled document system. By linking documents to IntelliPERMIT, they still remain in the controlled system, while at the same time being visible to those that most need them.

By linking controlled documents to IntelliPERMIT a number of other benefits are possible. Some specific examples are:

- The ability to automatically link rescue plans and drawings to items of equipment where confined space permits are being generated.

- The ability to link standard isolation lists to controlled P&ID’s.

- The ability to show permit to work procedures and related standards directly from the IntelliPERMIT home page.

- The ability to attach controlled and uncontrolled documents to individual permits – for example risk assessment templates or photographs.

- The ability to include important emergency procedures and site information directly on the permit certificate.

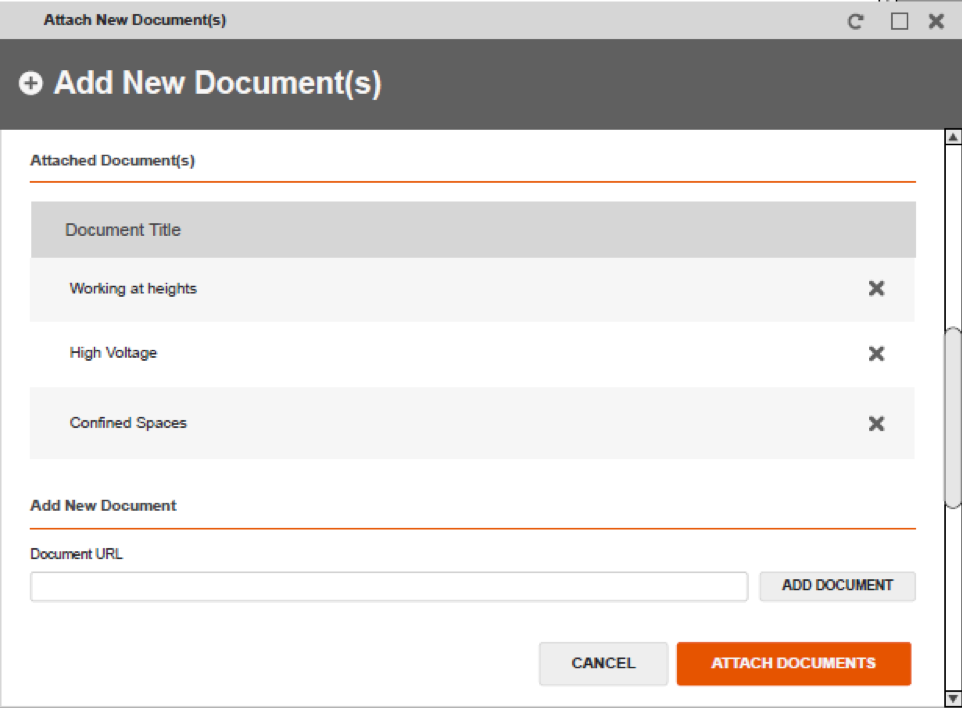

In the example below, a document is being added to IntelliPERMIT and is linked to specific hazards. Then when these hazards are identified as relating to a particular job, the linked documents (which might be standard operating procedures) are made available in the permit itself:

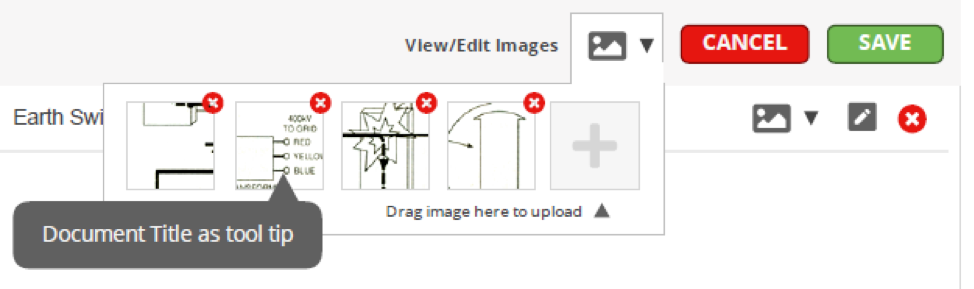

Another example screenshot shows how drawings might be presented when viewing a permit on the system:

Optimising the way controlled safety documents are linked into IntelliPERMIT

Linking controlled documents into the permit system does require some upfront planning during configuration of the relevant systems. Only relevant documents should be linked, and ideally only in the context where they are required (e.g. plant area, or step in the process). Furthermore, the documents themselves need to be written in plan, easy to understand and clear language, suited for the plant personnel or workers.

Fortunately, the interfaces themselves are not that complex and Adapt IT’s IntelliPERMIT consultants have experience in integrating IntelliPERMIT with a number of document management systems. It is recommended that these document links be reviewed from time to time to ensure that all changes have been properly incorporated into the permit system. This review can be included in the scope of a regular system health check.

In conclusion

Linking controlled documents to the permit is a simple concept that has a significant impact on the way safety management systems such as ISO 45 000 are implemented in practice. The permit to work is where the “rubber hits the road” and the most logical place to have the most important safety procedures and information collated. IntelliPERMIT does not replace the requirement for a proper safety management system, nor for a proper document control system. It does however make such systems effective where it most matters, in the field and on the plants where dangerous work is taking place.

To learn more about IntelliPERMIT and linking controlled documents please contact the IntelliPERMIT team at Adapt IT.

Continue Reading

Q&A with IntelliPERMIT Consultant Lungelo Majozi

Explore the advantages of electronic permit to work (e-PTW) systems over paper methods, from faster investigations to specific hazard management. Learn how e-PTW enhances safety, prevents redundant isolations, and ensures accountability. Discover future trends like 3D modeling. IntelliPERMIT automates tasks, improves communication, and reduces costs, making workplaces safer and more efficient.

Powering Safety Innovations: An Exclusive Q&A with IntelliPERMIT Consultant Shirley Breytenbach

IntelliPERMIT transforms permit management with streamlined processes, competency-based approvals, and real-time visibility. Ensure regulatory compliance, enhance worker safety, and boost operational efficiency. The system offers seamless integration, empowering organisations to proactively mitigate safety risks.

Safety Software Implementation Success : An Exclusive Q&A with IntelliPERMIT Consultant Henry Boshoff

Unlock safety software success with IntelliPERMIT: Prioritise key features, secure user buy-in through change management, and foster collaboration. Set measurable goals, leverage incident data for proactive decisions, and ensure intuitive search capabilities. Streamline report generation and simplify scheduling and management of training, drills, toolbox talks, and audits. Overcome adoption challenges by addressing pain points and customizing the software. Enhance user adoption with automation and user-friendly interfaces. Evaluate safety software providers based on knowledge, experience, and adherence to standards—IntelliPERMIT excels. Easily integrate with existing systems through standard APIs. Opt for web-based software for accessibility and usability. IntelliPERMIT enhances safety practices and compliance.